Add to Cart

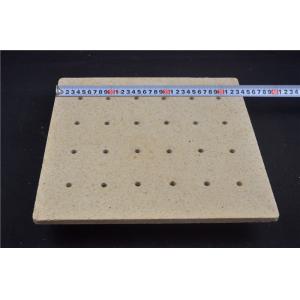

Kam Tai Refractory Cordierite slab 340*340*10mm of kiln furniture

1. Details

Cordierite ceramics are well known for their low thermal expansion and refractory character. Although cordierite is available as a powder, when we use the term we are generally talking about ceramic that went into the kiln as ordinary composite of ceramic powders but emerges as a cordierite crystalline matrix (grown by the firing process tuned to its needs).

Cordierite makes the ceramic manufacture of products like catalytic converters possible. They constantly heat up and cool down quickly and must not crack because of the shock. These converters get their thermal shock resistance properties from a bonded matrix of low-expansion cordierite crystals. These crystals form during firing between 1300 to 1400C (interestingly, cordierite crystals have a lesser thermal expansion along one axis than another). Thus, the better the density of the precursor mix and controlled the firing the better the properties of the cordierite material are.

The ideal chemistry to produce the crystals is 13.8% MgO, 34.8% Al2O3 and 51.4% SiO2 (2MgO, 2Al2O3, 5SiO2). Talc, kaolin and raw alumina powder can be blended to produce this chemistry (other materials are also used e.g. aluminum hydroxide, steatite and other MgO minerals). Compound materials (like kaolin and talc) react better than pure oxide materials (like MgO, Al2O3, SiO2). Materials of finer particle size react better.

2. Technical parameters

|

Item and Descriptions

|

Specifications Offered

|

||

|

Al2O3 (%)

|

40~48

|

||

|

SiO2 (%)

|

45~48

|

||

|

MgO (%)

|

5~8

|

||

|

MOR(MPa)

|

20℃

|

14

|

|

|

1250℃

|

12

|

||

|

Bulk Density(g/cm3)

|

2.0

|

||

|

Open Porosity(%)

|

28

|

||

|

Phase composition(%)

|

Mullite

|

55

|

|

|

Cordierite

|

30

|

||

|

Max. Service temperature ℃

|

1280

|

||

WE HAVE PROFESSIONAL DETECTING EQUIPMENTWe are aimed to improve R&D and production process and equipment. Moreover, we cooperate with famous university such like Liaoning University of Science and Technology, Beijing University of Science and Technology.

3. Our Service

- We will offer our best price.

- Your inquiry will be replied within 24 hours.

- Experienced staff can give you professional suggestions.

- We ensure you high quality products and timely delivery.

- We offer complete and good after-sale service.